Solution for challenges in small parts machining

Molded Sharp Edge Chipbreaker

SK/SKS

ChipbreakerNew PVD coating with higher performance

Molded Sharp Edge Chipbreaker

New PVD coating with higher performance

1st Recommendation for Finishing

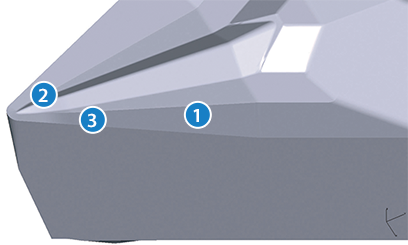

Rake face, bottom face, and chipbreaker face

ensure properly curled chips

Optimized Chipbreaker HeightStabilized chip control when machining at high feed rates

Improved chip evacuation when machining at large D.O.C.

1st Recommendation for Semi-finishing

Stable chip evacuation in large D.O.C.

with large rake angle

Improved chip control in small D.O.C.

with the breaker projecting out to the corner tip

Reduced cutting force as the cutting edge is lowered towards the center of the workpiece

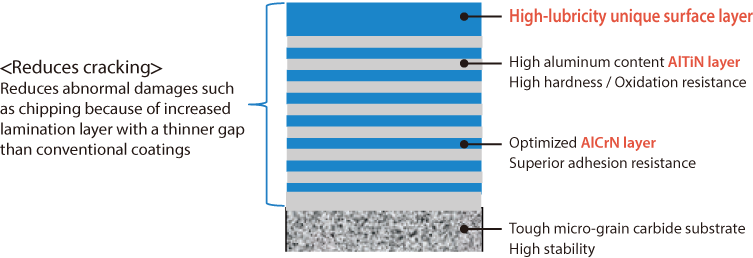

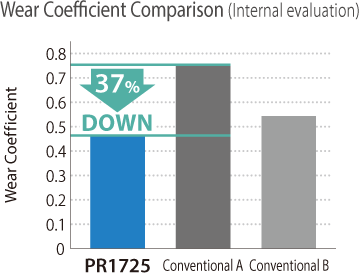

Newly Developed PVD Coating MEGACOAT NANO PLUS

High hardness with nano laminated film layer properties internal stress optimization reduces chipping

Special surface layer with great lubricity reduces adhesion

Excellent oxidation resistance. Superior high temperature properties maintains good performance in steel, stainless steel and free-cutting steel

Tough micro-grain carbide substrate provides stable machining