Excellent hole accuracy with a low cutting force design

- Low cutting force design improves hole accuracy

- Optimal web thickness limits deflection

- Fine chip breaking even in deep hole drilling applications

- Easy insert replacement

- Long tool life and stable machining of various workpieces

- HQP high precision insert for steel machining and chamfering attachment are added to lineup

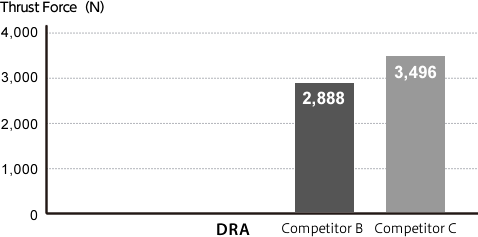

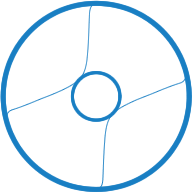

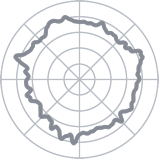

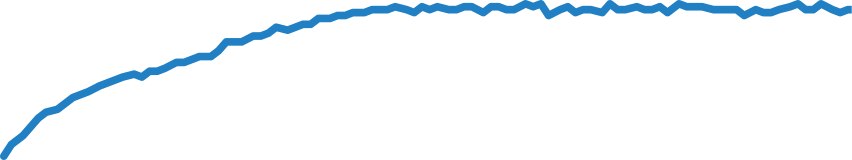

Low cutting force design improves hole accuracy

Low cutting force design improves hole accuracy

Special chisel edge with S-curve reduces thrust force and controls vibration.

-

DRA

-

Standard Drill

Cutting Conditions: Vc = 120 m/min, f = 0.25 mm/rev

Drilling Diameter φ14, Drilling Depth 45 mm, Wet, Workpiece: 1049(C50)

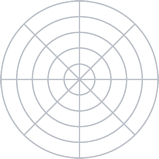

Optimal web thickness limits deflection

Optimal web thickness limits deflection

Improved hole accuracy by controlling drill deflection with a 20% thicker web compared with Competitor A.

-

DRA

-

Competitor A

-

DRA

-

Competitor D

-

Competitor E

| Roundness | 18.7μm | 31.1μm | 27.3μm |

|---|---|---|---|

| Cylindricity | 23.6μm | 34.3μm | 30.1μm |

Cutting Conditions: Vc = 120 m/min, f = 0.3 mm/rev

Drilling Diameter φ14, Measurement Position 55 mm, Wet Workpiece: 1049(C50)

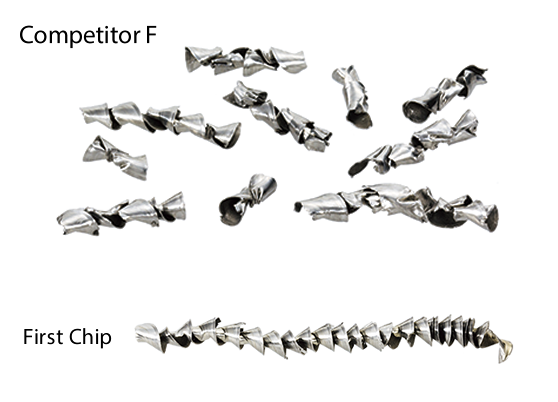

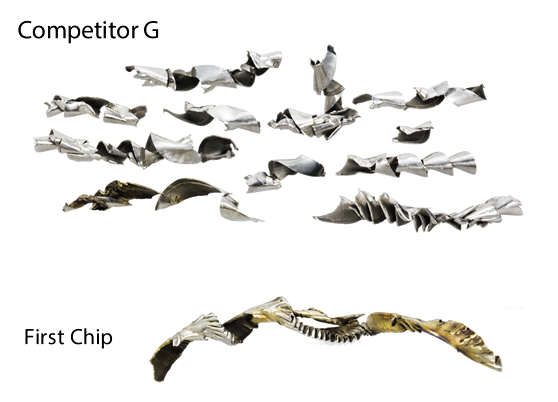

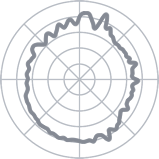

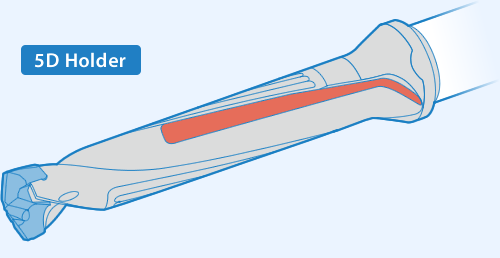

Fine chip breaking even in deep hole drilling applications

Fine chip breaking even in deep hole drilling applications

Optimized chip thinning for stable chip evacuation.

Support groove with wider flute (5D, 8D) enables smooth chip evacuation.

Diameter φ14, Drilling Depth: 70 mm, Wet Workpiece: 304(X5CrNi18 10)

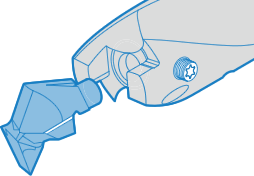

Easy insert replacement

Easy insert replacement

Replace insert without removing screw.

-

Replace insert without removing screw

-

Install the insert onto tooholder (align insert guide line with screw position)

-

Fix the insert by tightening the screw

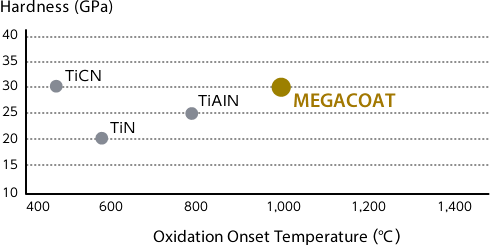

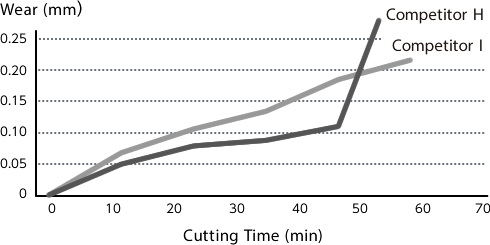

Long tool life and stable machining of various workpieces

Long tool life and stable machining of various workpieces

1st Recommendation

MEGACOAT NANO grade PR1535 is used to machine various materials from steel to stainless steel, with the combination of a tough substrate and a special nano layer coating.

Cutting Conditions: Vc = 60 m/min, f = 0.2 mm/rev, Drilling Diameter φ14, Drilling Depth: 70mm, Wet Workpiece: 4140H(42CrMo4)

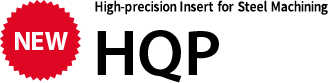

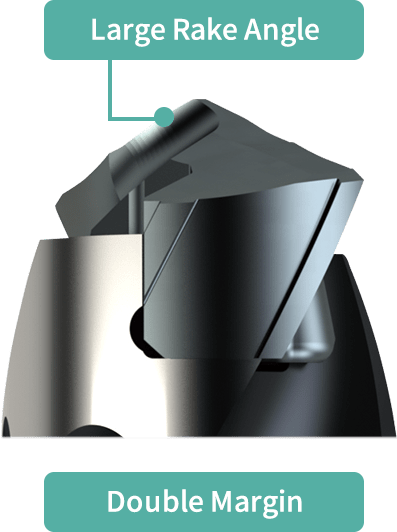

Configure your drill according to your demand choosing from our different inserts

Configure your drill according to your demand choosing from our different inserts

Four type of inserts specially designed to offer best results for your

application

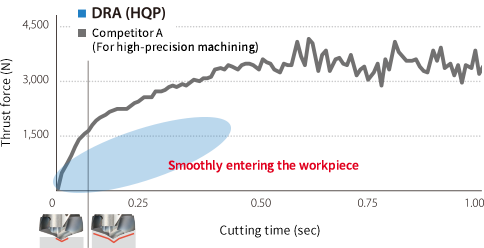

Improved centripetal forces delivers high-precision machining.

Capabilities for both machining centers and lathes.

Special two-step bottom, large rake angle and double margin design reduce initial shock for higher-precision machining.

when entering the workpiece

Cutting Conditions : Vc = 100 m/min, f = 0.25 mm/rev, H = 30 mm, Wet Workpiece : S50C ø16 (3D)

Case Studies

Attachment A283(17100)

Vc = 70 m/min (n = 1,240 min-1)

f = 0.23 mm/rev (Vf = 285 mm/min)

Drilling Depth 100 mm

Wet (Internal coolant)

With center hole drilling

SF25-DRA180M-8

DA1800M-GM PR1535

Competitor J applied a peck cycle to avoid chip clogging. DRA controlled chip evacuation without pecking. (User evaluation)

Plate 304(X5CrNi18 10)

Vc = 60 m/min (n = 2,120 min-1)

f = 0.12 mm/rev (Vf = 254 mm/min)

Drilling Depth 15 mm

Wet (Internal coolant)

SS16-DRA090M-3

DA0900M-GM PR1535

DRA extended the tool life by 5 times compared to Competitor K. DRA maintained

stable machining and excellent surface fininsh with less cutting noise.

(User evaluation)